Our Brochures

Download

Precision Sealless Pumps Pvt. Ltd. is a leading provider of innovative and reliable pumping solutions.

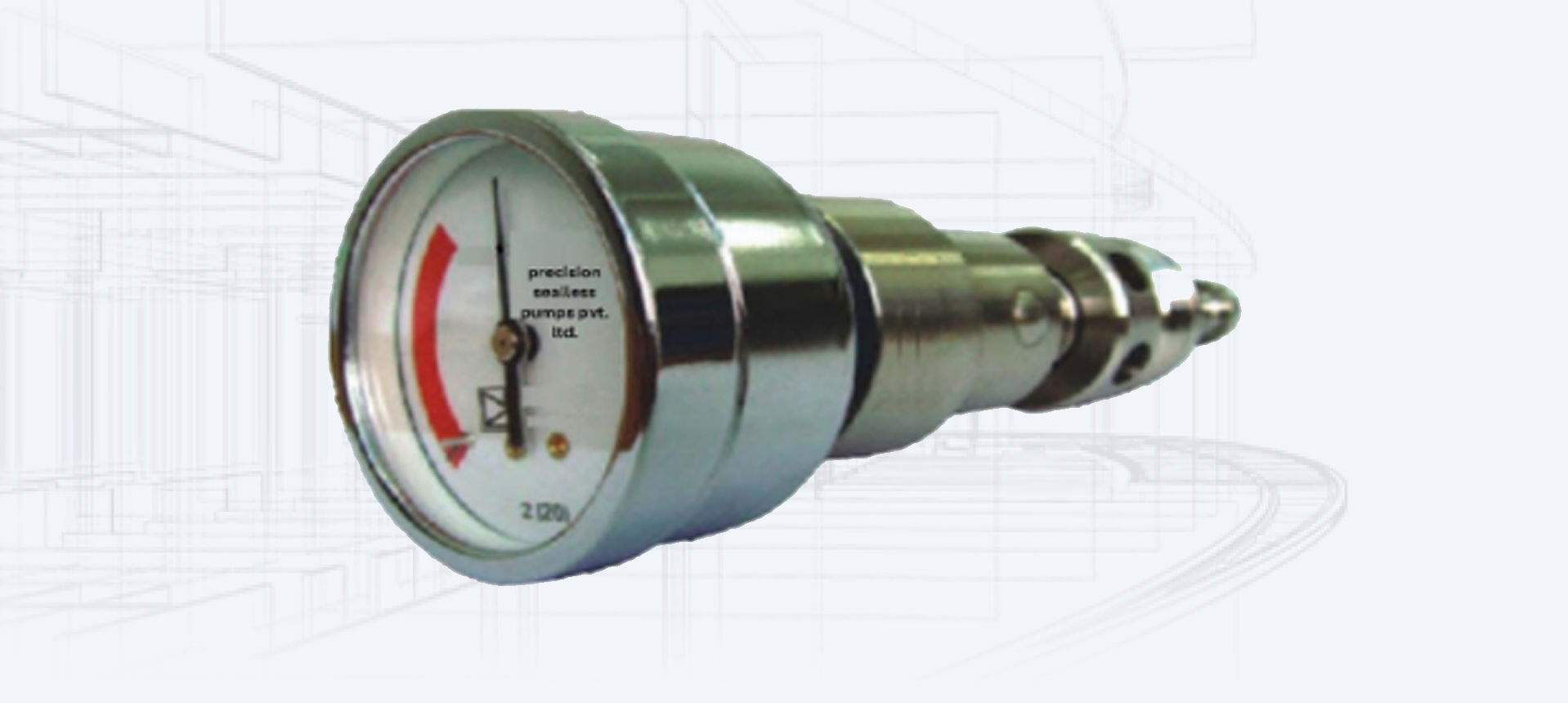

At Precision Sealless Pumps Pvt. Ltd., we provide Manual Bearing Monitors designed to enhance pump reliability by enabling real-time monitoring of bearing conditions. Our solutions help detect early signs of wear, preventing costly downtime and ensuring optimal performance.

The Bearing Monitor Addresses a critical issue common to all Seal less Pumps by Detecting bearing wear, enabling routine maintenance before significant motor damage happens. It monitors bearing wear in both axial and radial direction. This unique design features a gas-filled gauge, mounted on the rear bearing housing. The monitor’s contact to fits into a cavity in the shaft’s end nut, and the clearance between then indicates then maximum allowable bearing wear.

Early Fault Detection: Identifies bearing wear before critical failure.

Cost-Effective Maintenance: Reduces unplanned downtime and repair costs.

User-Friendly Operation: Simple to use for routine manual inspections.

Durable Construction: Designed to withstand harsh industrial environments.

Mechanical Bearing Indicators: Provides a visual alert for bearing wear.

Handheld Temperature SensorMeasures bearing temperature for early issue detection.

Vibration Analysis Tools: Helps detect misalignment and wear in rotating components.

Our Manual Bearing Monitors are ideal for:

Chemical and Process Industries

Water and Wastewater Management

Oil and Gas Sector

Power Generation

Food and Beverage Processing