Our Brochures

Download

Precision Sealless Pumps Pvt. Ltd. is a leading provider of innovative and reliable pumping solutions.

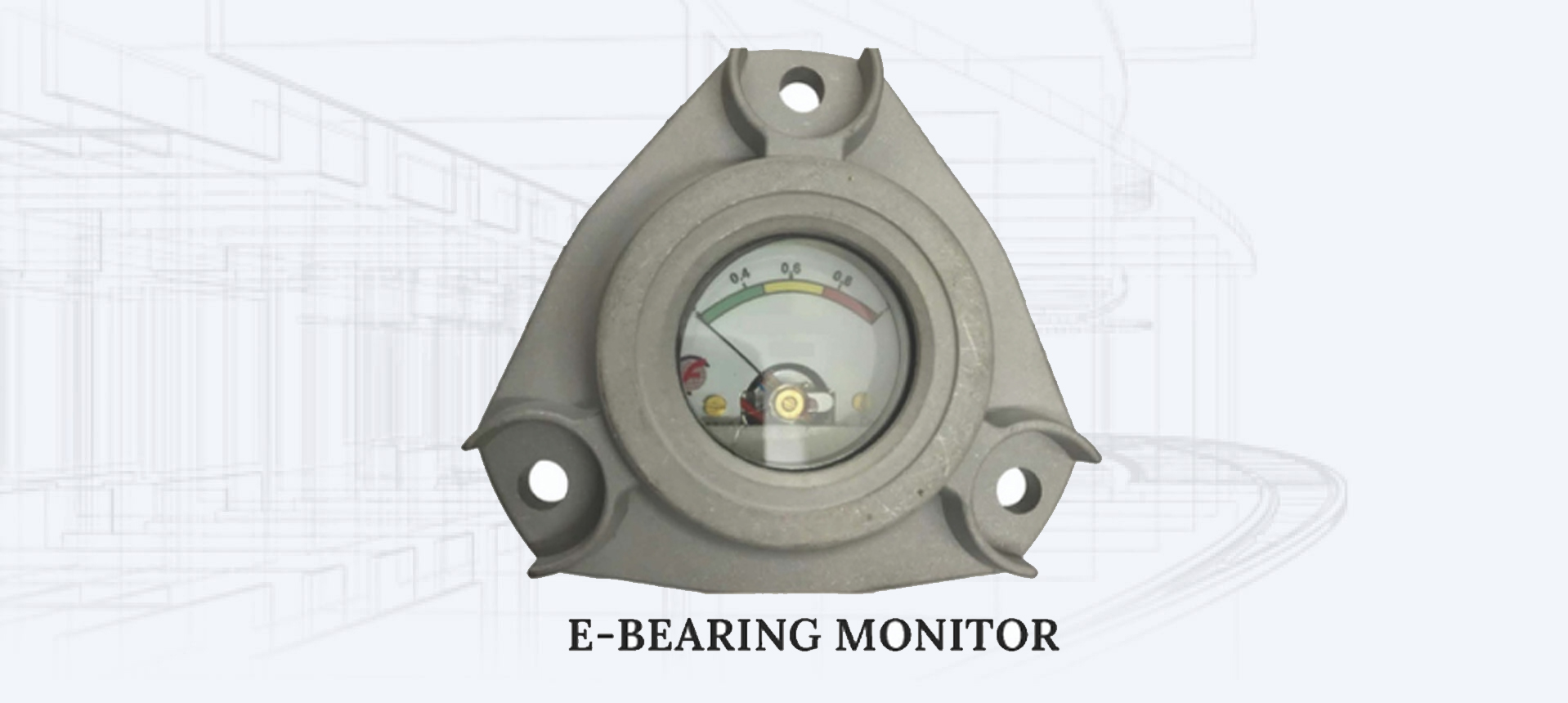

At Precision Sealless Pumps Pvt. Ltd., we offer state-of-the-art E-Bearing Monitors designed to provide real-time monitoring of bearing conditions in pumps. Our advanced electronic monitoring systems help detect early warning signs of wear, ensuring proactive maintenance and preventing unexpected failures.

The E-Bearing Monitor Operates on The Principle Of Induced Voltage. The Current Flowing Through The Stator Winding Generates A Magnetic Filed in The Ebm Coils. Additionally, The Rotor Generates Its Own Magnetic Filed As a Result Of the Currents Induced Within it . These Induced Currents In The Rotor Arise From The interaction with The Stator’s Magnetic Flied.

Real-Time Monitoring: Continuously tracks bearing performance and alerts for anomalies.

Early Fault Detection: Identifies potential issues before they lead to costly breakdowns.

Remote Monitoring Capability: Enables data access and analysis from any location..

Enhanced Operational Efficiency: Reduces downtime and extends equipment lifespan.

Temperature Sensors: Monitors bearing temperature to prevent overheating..

Vibration Sensors: Detects irregular vibrations indicating misalignment or wear.

Wireless Connectivity: Enables remote diagnostics and predictive maintenance.

Automated Alerts: Sends notifications for maintenance actions to prevent failures.

Our E-Bearing Monitors are ideal for:

Chemical and Process Industries

Water and Wastewater Management

Oil and Gas Sector.

Power Generation

Food and Beverage Processing