Our Brochures

Download

Precision Sealless Pumps Pvt. Ltd. is a leading provider of innovative and reliable pumping solutions.

Our PMP Series (Precision Magnetic Pump) delivers cutting-edge seal-less magnetic drive technologyfor safe, reliable, and maintenance-free pumping of hazardous, corrosive, and high-temperature fluids.

Looking for a pump that ensures zero leakage, low maintenance, and high operational safety? Magnetic Drive Pumps from PRECISION SEALLESS PUMP are your ideal solution. As a trusted manufacturer, supplier, and exporter, we deliver high-performance mag drive pumps for a wide range of chemical, pharmaceutical, and industrial applications.

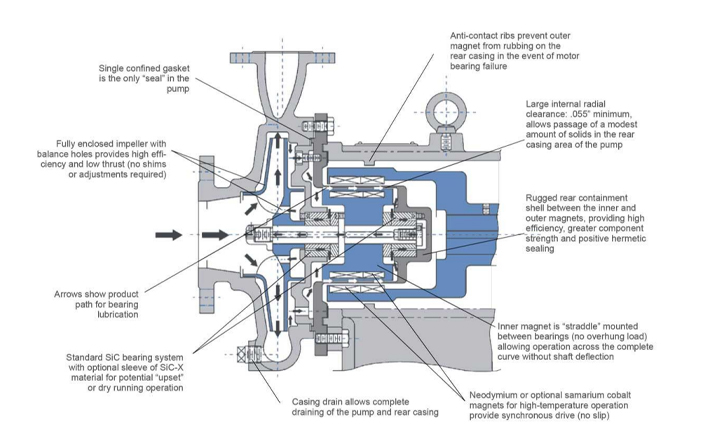

A Magnetic Drive Pump, also known as a sealless pump, is designed without any mechanical seals, eliminating the risk of leakage. Instead of a direct shaft connection, it uses a magnetic coupling to transfer torque. This innovative design makes it ideal for handling corrosive, hazardous, or toxic fluids.

At PRECISION SEALLESS PUMP, we specialize in engineering excellence and leak-proof performance. Our Magnetic Drive Pumps are built to last, even in the most demanding environments. Here's why industries worldwide rely on us:

As a leading Magnetic Drive Pump manufacturer and exporter from India, PRECISION SEALLESS PUMP exports to regions like the Middle East, Africa, Southeast Asia, Europe, and the Americas. Our commitment to quality, safety, and innovation sets us apart in the global marketplace.

Explore Our Magnetic Drive Pump Range Today!

Contact PRECISION SEALLESS PUMP for technical consultation, customized solutions, or bulk orders. We’re here to support your fluid handling needs with precision and reliability.

We are one of the best Magnetic Drive Pump manufacturer, Magnetic Drive Pump Exporter, Magnetic Drive Pump Supplier in Mumbai, India. Please visit here for order!!

Magnetic-drive pumps are a design of mangnetically - driven chemical -processs pump which elimate the need for shaft sealing. This greatly reduces the initial cost of the pump as well as day - to - day operational costs as there aren’t any mechanical drive pumps that provide superior performance without the need for mechanical seals.

| Maximum Flow | 2000 GPM |

| Maximum Head | 430 FT |

| Liquid Temperature | -150° F to +800° F |

| Maximum Power | up to 200 HP |

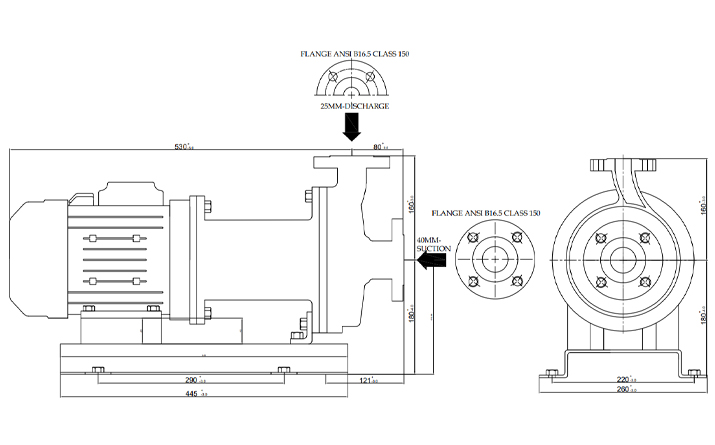

| Connections | 150lb RF std. or opt. 300lb RF ANSI Flanges |

| Bearings | SiC, SiC-X opt. for Upset or Dry-run Conditions |

| Working Pressure | 285 psig |

| Impeller | Enclosed |

| Speeds | Up to 2900 rpm |

| Magnets | Neodymium or Samarium Cobalt for High Temp |

| Motor | NEMA or IEC Frame Mounted |